With the support of hardcore equipment, JKTRAFFICLIGHT has forged outstanding capabilities in traffic signal products

In the field of manufacturing Traffic Signal products, powerful hardware equipment is the key to ensuring product quality and production efficiency. As a company dedicated to the production, manufacturing and research and development of traffic signal products for 23 years,JKTRAFFICLIGHT has demonstrated strong capabilities with its advanced and complete equipment configuration, and has become a highly regarded leader in the industry.

The electronic workshop of JKTRAFFICLIGHT Company covers an area of over 2,000 square meters and is equipped with 1 SMT production line, 2 through-hole assembly production lines and 2 assembly production lines. The SMT production line has high-precision surface mount capabilities and can accurately complete the mounting of various electronic components for traffic signal products, laying a solid foundation for the stable operation of the products. Two machine insertion production lines are operating efficiently, significantly enhancing the speed and accuracy of the electronic component insertion process. The two assembly production lines strictly follow standardized procedures to ensure that each traffic signal product meets strict quality standards during the assembly process, guaranteeing the consistency of product performance.

Not only that, JKTRAFFICLIGHT Company also has a shell processing workshop of over 1,000 square meters, which is equipped with nearly 50 advanced processing machines of various types, including bending machines, shearing machines, plasma cutting machines, laser cutting machines, etc. The bending machine can precisely bend metal plates to create various shapes that meet the design requirements of traffic signal product shells, ensuring the structural stability of the shells. The shearing machine can efficiently cut raw materials and ensure the accuracy of the sheet size. Plasma cutting machines and laser cutting machines, with their high-precision cutting capabilities, can achieve micron-level processing accuracy for shell components, ensuring a perfect fit among all parts. This not only enhances the appearance and texture of the product but also provides solid protection for the internal electronic components, enabling them to adapt to various outdoor environments and extend the product's service life.

Relying on these advanced devices, JKTRAFFICLIGHT has achieved an integrated and efficient operation from electronic component processing to shell manufacturing in the research and development and production of traffic signal products. It can not only respond quickly to market demands but also ensure the high quality of products through exquisite craftsmanship.

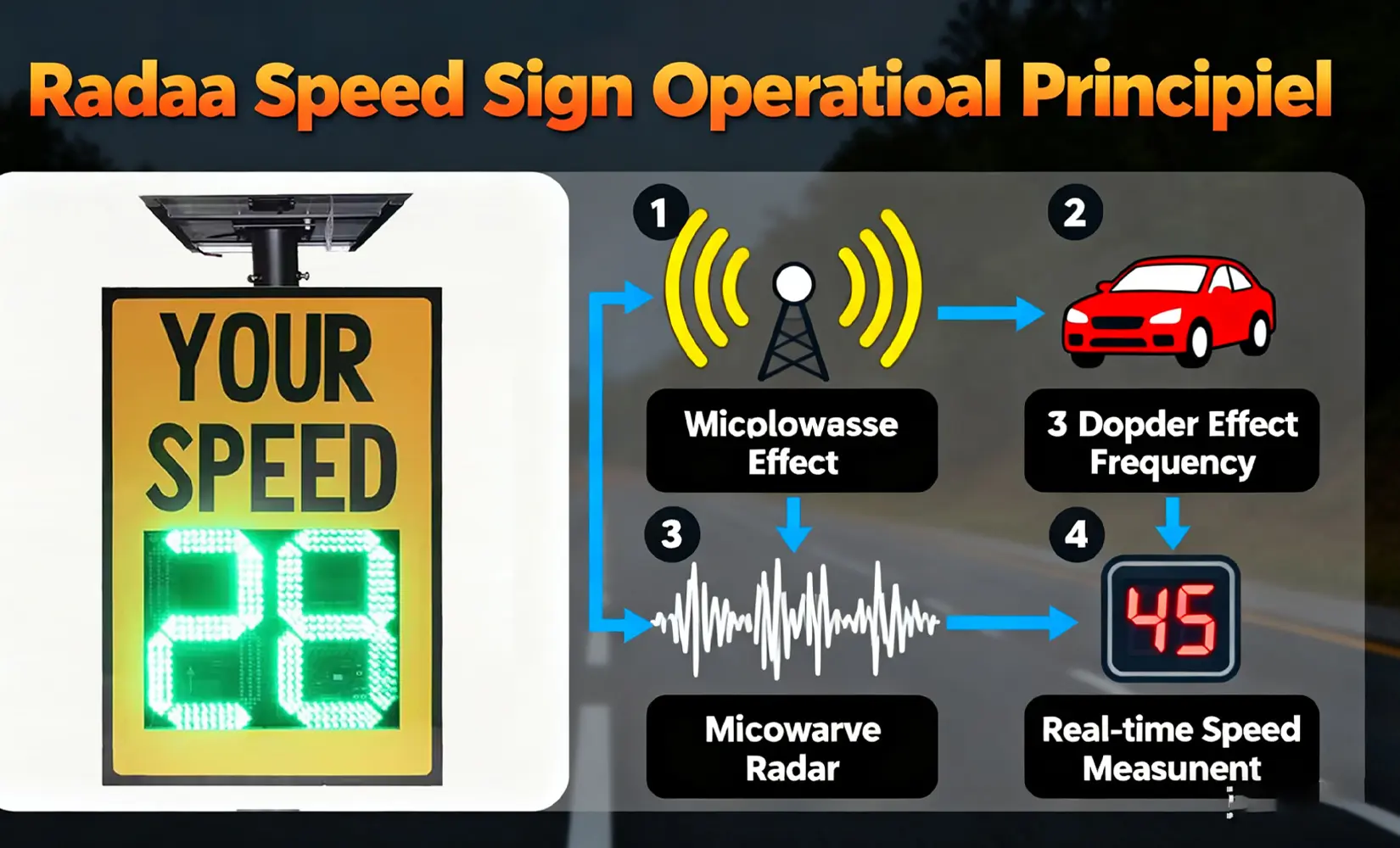

We are well aware that stable and reliable signal products are the lifeline of urban transportation. Advanced equipment is the foundation, and we transform it into outstanding product power that meets your needs. Whether it is standardized Signal Lights, road traffic signal control machines, or radar speed signs, our manufacturing system can provide strong quality assurance and delivery capabilities. ChoosingJKTRAFFICLIGHT means choosing a reliable product and strong strength guarantee. We look forward to working hand in hand with our customers to build a safe and efficient traffic environment.

We look forward to building a safer, more efficient and smarter transportation future together with you!